Oyster Girl Oysters

Saint Michaels, MD

Oyster Girl Oysters

Saint Michaels, MD

Operations

We grow our oysters in cages positioned on the water's surface. By utilizing the water's natural current and nutrient availability, oysters grown on the water's surface experience faster growth rates and improved flavor profiles compared to bottom-cultivated counterparts. Additionally, surface-grown oysters are less prone to predation and siltation, leading to a higher survival rate and increased overall yield.

Each year we purchase about 60,000 oyster seed with the expectation, based on Degremont, Garcia, Frank-Lawale & Allen (2012), of having 50% reach market size in two years. Our projections are based on an 80% year-to-year survival rate which translates to a 51% seed-to-harvest survival rate (.8 x .8 x .8 = .51).

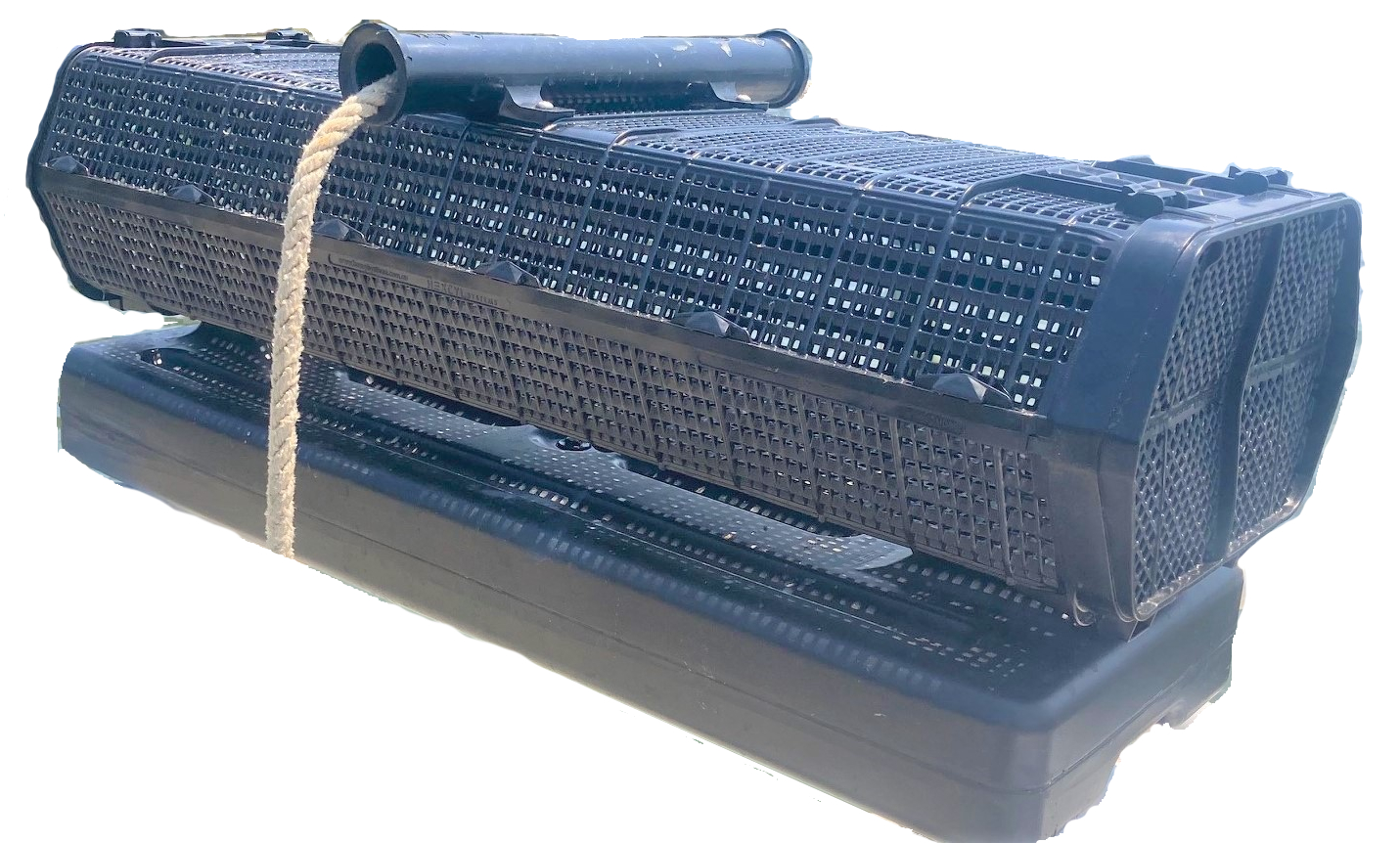

We primary use FlipFarm® baskets which are  hard 29" by 12" plastic baskets with a float on one side and an axle on the other, We also use traditional Vexar® bags which are 33" x 17" x 3.5" with two torpedo shaped pontoons on one side. Some of our cages use gray XPS foam floation (2" attic insulation board) and, so far, we have been happy.

hard 29" by 12" plastic baskets with a float on one side and an axle on the other, We also use traditional Vexar® bags which are 33" x 17" x 3.5" with two torpedo shaped pontoons on one side. Some of our cages use gray XPS foam floation (2" attic insulation board) and, so far, we have been happy.

The axles are tubes which span the narrow dimension of the containers. Long line ropes go through the axles and are terminated using chain and Danforth® anchors. Every week during the summer, the cages are flipped with the pontoon side down so the entire cage and oysters are temporarily out of the water, allowing the sun and air to kill algae, barnacles, cushion moss, and other growth that would otherwise cause fouling and compete for food. We are the only farm in Maryland using this system. With cages so positioned on the long lines, it takes approximately 20 minutes to flip a row of 110 cages by hand and under a minute using our own patent pending system.

The axles are tubes which span the narrow dimension of the containers. Long line ropes go through the axles and are terminated using chain and Danforth® anchors. Every week during the summer, the cages are flipped with the pontoon side down so the entire cage and oysters are temporarily out of the water, allowing the sun and air to kill algae, barnacles, cushion moss, and other growth that would otherwise cause fouling and compete for food. We are the only farm in Maryland using this system. With cages so positioned on the long lines, it takes approximately 20 minutes to flip a row of 110 cages by hand and under a minute using our own patent pending system.

We use the following density plan based on an evaluation we conducted on expected cage volume (Rudner, 2020). We have an on-line calculator to help us estimate the volume of oysters for a given size.

| Density plan | ||

| Date | Seed Size | Density |

| May, Year 1 | 2-8 mm | 20,000 seed per bag . |

| July, Year 1 | 9-43 mm | 500 seed per bag |

| June, Year 2 | 43-76 mm | 125 seed per bag |

| May, Year 3 | >76 mm | 75 seed per bag |

By varying densities, we make very efficient use of the expensive floating cages and far fewer cages will be needed to achieve our initial goal of 30,000 harvest sized oysters per year. With each crop rotation, we tumble and sort the oysters using our homemade sorter.

Degremont, Lionel, Garcia,C, Frank-Lawale, A. & Allen, Standish K. Jr. (2012). Triploid Oysters in the Chesapeake Bay: Comparison of Diploid and Triploid Crassostrea Virginica, VIMS Articles 342. Available online at:

https://scholarworks.wm.edu/cgi/viewcontent.cgi?article=1341&context=vimsarticles.

Rudner, Lawrence (2020). Create an Efficient Oyster-Sorting Schedule, East Coast Shellfish Growers Association Newsletter, October 2020 (Issue 4), pages 7,10,11. Available online at https://ecsga.org/wp-content/uploads/2020/09/ECSGA_NL_v4-20.pdf see also http://oystergirl.us/OysterVolModel.pdf for a more detailed version of the ECSGA paper.

Facilities

Facilities

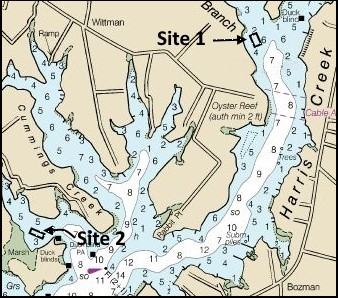

We have two lease locations, both selected for their proximity to our dock. The closer location, which is ¼ mile from our dock and 1.7 acres, is our primarily growing site. The other location, which is 2 miles from our dock and 1.9 acres, is for possible expansion. Both leases are for floating and bottom cages.